Precision Forged, Performance Delivered

K-13, New # 64, 8Th Street, Ambattur Industrial Estate, Chennai -600 058.

Precision Forged, Performance Delivered

K-13, New # 64, 8Th Street, Ambattur Industrial Estate, Chennai -600 058.

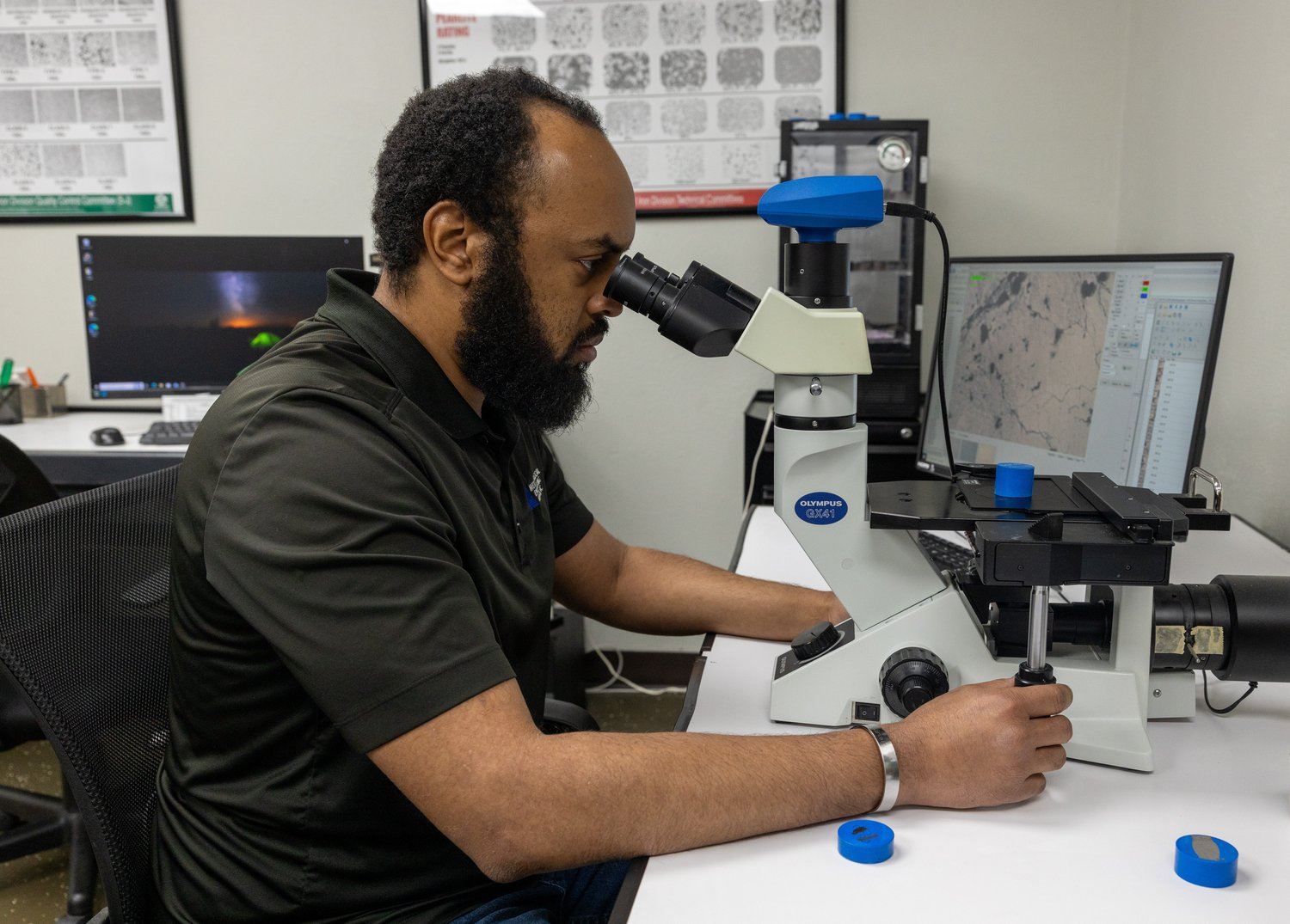

Metallurgical testing involves analyzing the internal structure and mechanical properties of materials to ensure they meet design and performance requirements. At R.K. Industries, our in-house metallurgy lab plays a vital role in verifying heat treatment results, validating raw material properties, and supporting failure analysis. This scientific approach ensures every component we produce is not only dimensionally accurate, but structurally sound — capable of withstanding real-world application stress.

We operate a complete, in-house metallurgical lab designed to support heat treatment, material validation, and structural analysis. Our capabilities include:

This lab enables us to close the loop between manufacturing and material science — a key advantage in critical component production.

01

Components are selected post-heat treatment or from batch samples

02

Samples are cut using abrasive tools to expose cross-sections

03

Mounted in resin and polished to lab-grade smoothness

04

Grain flow, hardness zones, and micro-defects are examined

05

Vickers testing determines surface and core hardness

06

Reports are generated for internal QA or client submission

Metallurgical testing is crucial for parts that undergo heat treatment or are exposed to high stress during operation.

With full in-house testing, we eliminate guesswork and reduce lead time for validation.

Our metallurgical lab enhances our overall quality framework and supports ISO/IATF compliance:

Our metallurgical testing isn't just about quality — it's about proof of performance.