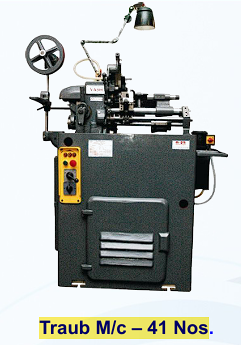

Traub Machines

(41 Nos.)

High-speed automatic lathes used for turning small to mid-size components. Ideal for mass production of precision parts with excellent repeatability in automotive and industrial applications.