R.K. Industries has adopted the highest-tier enterprise package of SUKI ERP, a purpose-built solution by Suki Software tailored for precision manufacturing environments. This robust system enables complete digital governance, covering all functional areas including production planning, procurement, quality control, human resources, dispatch, and finance. SUKI ERP streamlines operations by integrating departments, automating manual tasks, and ensuring real-time data visibility — from shop floor to top floor. With built-in Power BI dashboards, document revision control, automated alerts, and cross-platform support, the system empowers R.K. Industries to improve delivery timelines, reduce waste, and ensure full compliance with customer, industry, and statutory standards. It supports multi-user, multi-plant operations with unmatched traceability and flexibility.

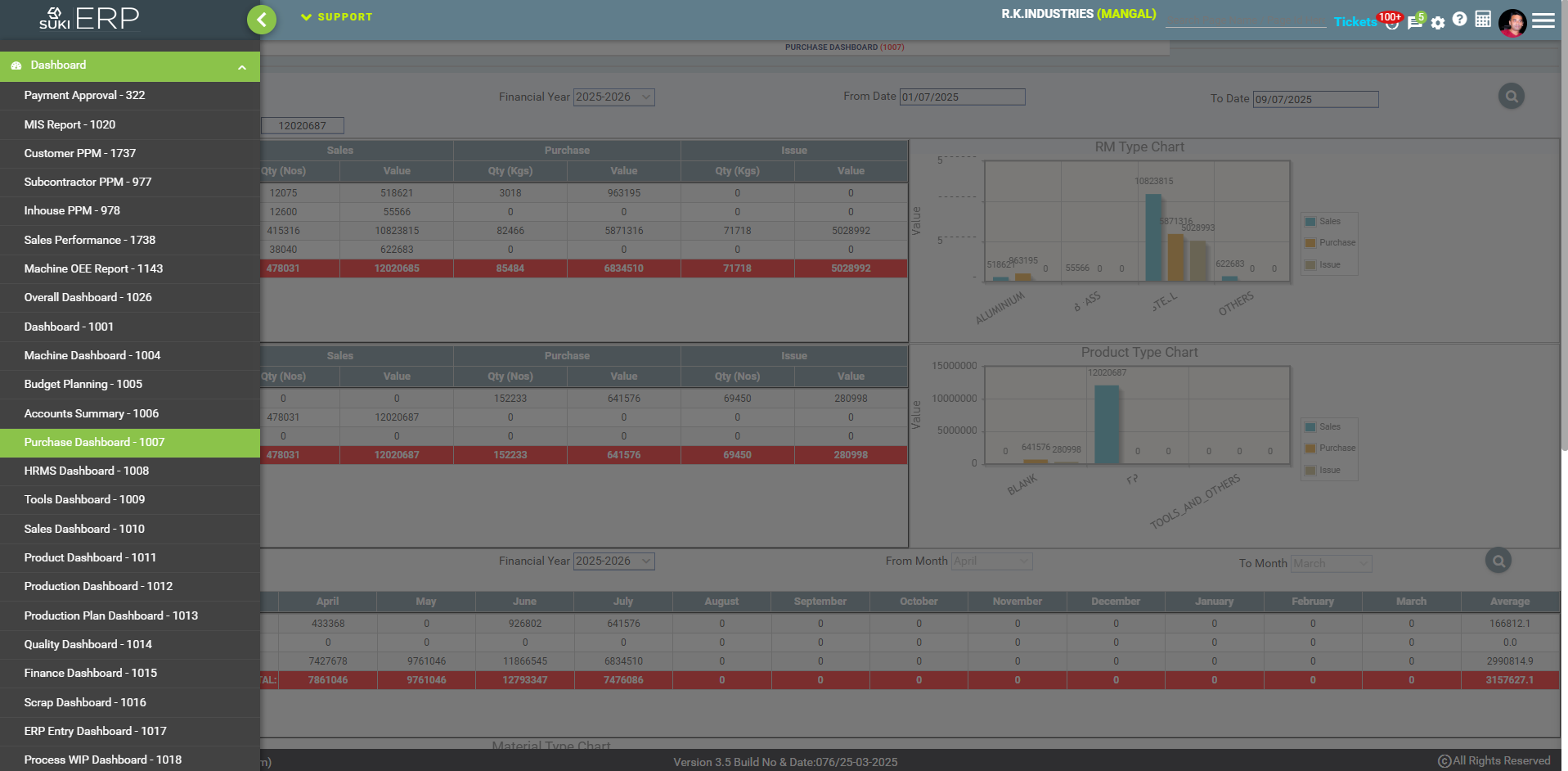

Live Dashboards & Reports

Access 150+ real-time reports and dashboards across inventory, production, quality, and dispatch — enabling fast, data-driven decision-making at all levels.

WhatsApp & Email Alerts

Get instant notifications on approvals, rejections, order status, and escalations through WhatsApp and email — stay updated anywhere, anytime.

Document Control & Revisions

Every drawing, SOP, or plan is revision-controlled with history tracking and access logs — ensuring accurate data flows across departments.

Role-Based Access & Audit Trails

Multi-layered user permissions and full audit trails secure the system, ensuring traceability, accountability, and protection of critical data.

End-to-End Module Integration

SUKI ERP connects MRP, CRM, HRMS, QMS, and finance into one seamless workflow, eliminating silos and improving efficiency across operations.

Cloud & Multi-Plant Hosting

Accessible from anywhere, SUKI ERP supports multi-location plants with centralized control and cloud hosting for uptime, security, and scalability.

.png)

.png)

.png)

.png)