Precision Forged, Performance Delivered

K-13, New # 64, 8Th Street, Ambattur Industrial Estate, Chennai -600 058.

Precision Forged, Performance Delivered

K-13, New # 64, 8Th Street, Ambattur Industrial Estate, Chennai -600 058.

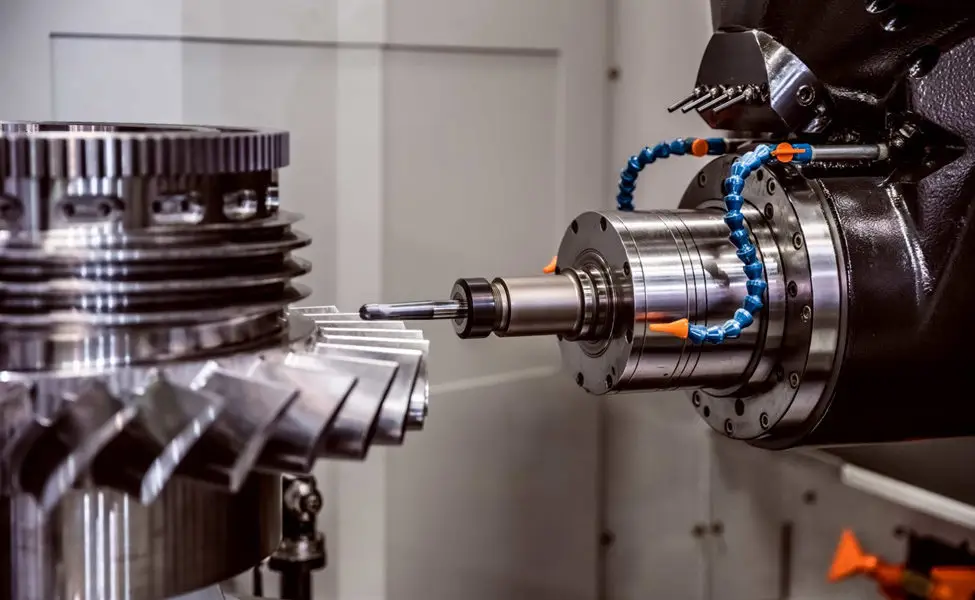

CNC (Computer Numerical Control) and VMC (Vertical Machining Center) machining are high-precision subtractive manufacturing processes used to create complex components from metal stock. At R.K. Industries, these services form a core part of our value chain, enabling us to produce parts with intricate geometries, tight tolerances, and excellent repeatability. With over 23 CNC lathes and advanced VMC systems in-house, we offer scalable and versatile machining for everything from shafts and sleeves to flanges and housings. This in-house capability allows us to maintain full control over quality, cost, and delivery timelines.

Our CNC & VMC machining setup is designed to handle a wide variety of components and materials with high accuracy. Key capabilities include:

This infrastructure allows us to deliver components with consistent accuracy and high surface finish, ready for final assembly or further finishing.

01

Machining paths are generated from 3D CAD models

02

Raw or forged parts are fixtured securely to prevent vibration or misalignment

03

Parts are cut, faced, bored, and profiled using CNC or VMC machines depending on geometry

04

Automated tool changes and fluid controls ensure surface quality and dimensional accuracy

05

Operators perform real-time measurements and tool wear checks

06

Final inspection includes dimensional validation using gauges and CMM where applicable

CNC and VMC machining services at R.K. Industries are crucial for finishing cold forged blanks or bar stock components. They are used for:

These parts demand high accuracy, low roughness, and reliable dimensional repeatability — all delivered through our precision machining ecosystem.

To ensure flawless output from every CNC or VMC machine, we integrate inspection checkpoints throughout the process. Our quality measures include:

Our machining services align with IATF, ISO 9001, and ISO 45001 certifications, ensuring traceable, high-performance outcomes from first part to last.