At R.K. Industries, quality is not just a target — it is the backbone of everything we do. We are deeply committed to delivering components that meet and exceed customer expectations in performance, reliability, and compliance. Our Quality Policy is built on a foundation of customer-centric thinking, process discipline, and proactive risk management. We ensure adherence to all statutory and regulatory standards while promoting a culture of continuous improvement. From raw material to final dispatch, every stage is governed by our robust Quality Management System, empowering us to deliver defect-free, timely, and efficient solutions to our valued clients.

We at R.K. Industries is committed to achieve customer satisfaction by meeting their requirements, providing quality products at the right time, complying statutory and regulatory requirements and continually improving the effectiveness of quality management system

01

100% On-Time Delivery

Ensure every product reaches the customer within the promised timeline, without exception.

02

100% Customer Satisfaction

Consistently deliver value that meets or exceeds client expectations.

03

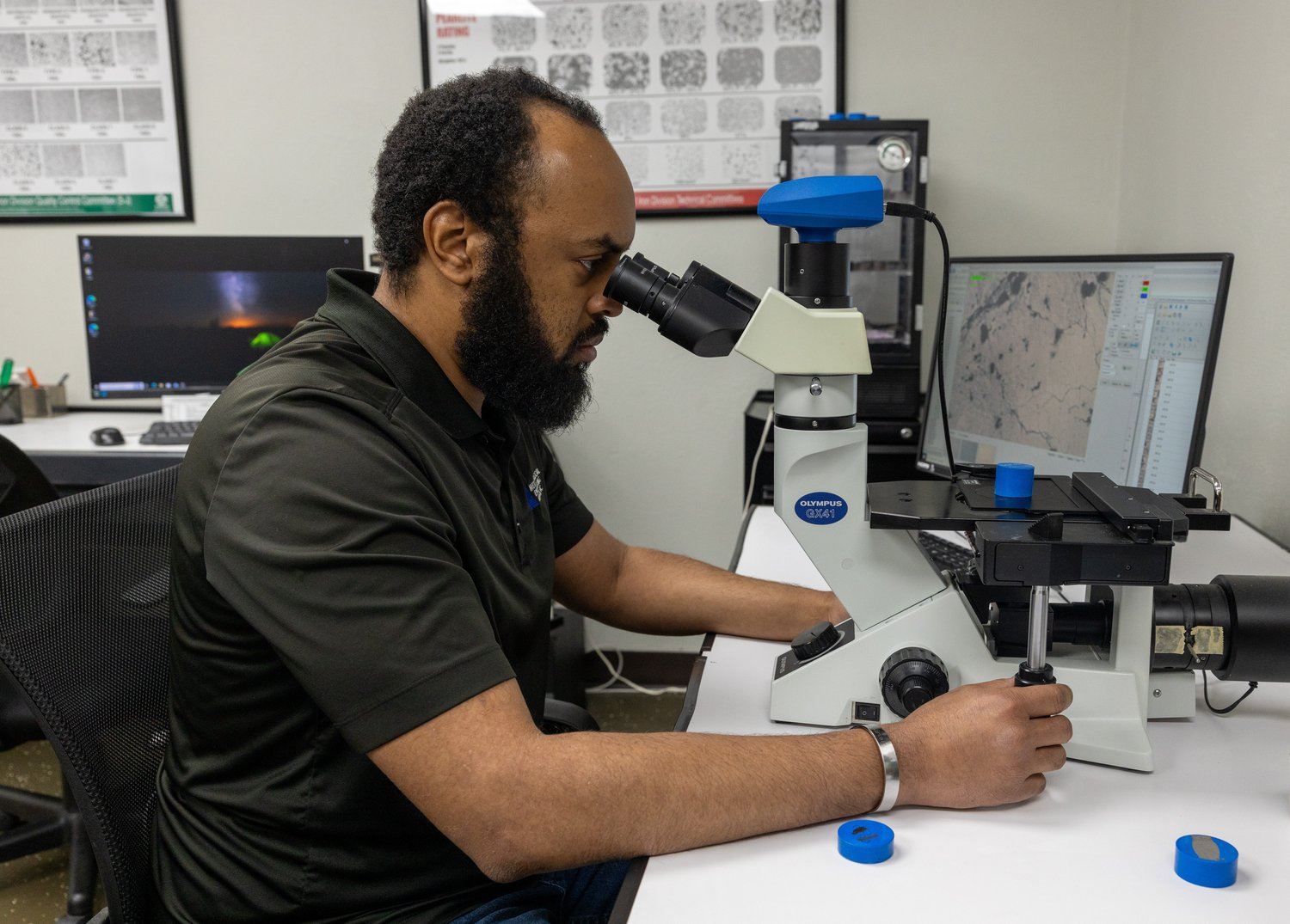

Reduce Rejection at All Stages

Implement rigorous inspection and process controls to minimize rework and scrap.

04

Zero Premium Freight

Optimize planning and execution to eliminate last-minute urgent shipments due to delays or quality issues.

05

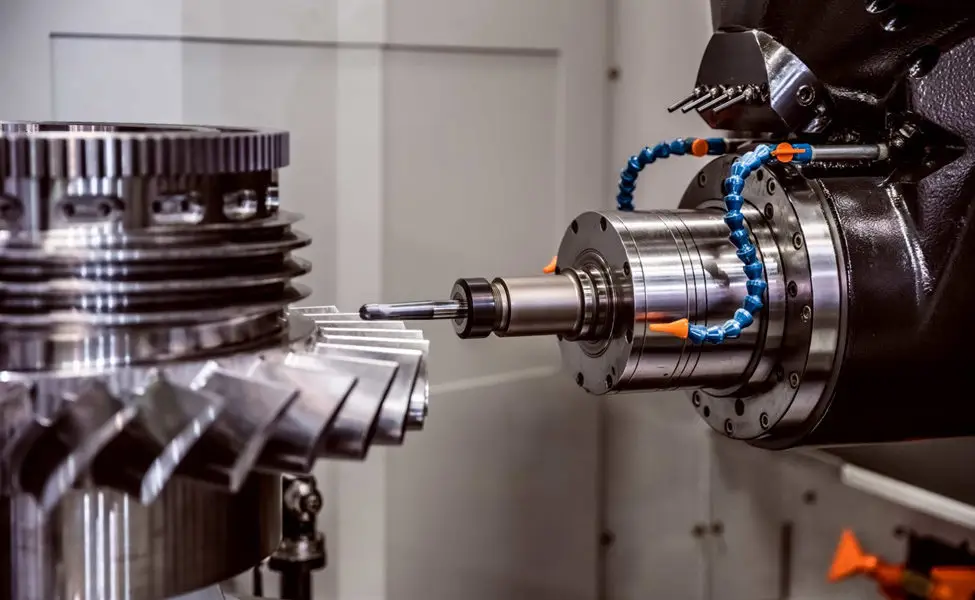

Effective Machine Utilization

Maximize the productive use of equipment through smart scheduling and maintenance.

06

Achieve 85% Production Efficiency

Streamline operations and eliminate inefficiencies to meet or surpass production efficiency targets.